Why Bales bursting

It is important to understand and appreciate the various factors that determine how safe and secure your bale is. It may only need to remain intact for a short time; alternatively, it could be required to remain wrapped and fully intact for a whole year or more. Consider:

- the actual type of crop and how it will be used.

- how and where the bale will be stored.

- how the bale will be handled.

- how many times the bale will be handled.

- the weather conditions when it is baled and when and where it will be stored.

Round baling with netwrap is the most convenient and least expensive way of wrapping your bale. Wrapping with netwrap reduces costs by being faster than using twine and offers much better protection to the crop than twine ever could. However, the actual security of your valuable bale is down to you and how well you know and use your baler. It is very important that a MINIMUM of NOT LESS THAN 2 layers of net are applied to the bale, as there are many ways that the ACTUAL amount of net applied can be LESS than the baler is set to apply.

Baler accuracy

| Most modern balers are equipped with net application systems, controlled by an in-cab control box (some lower specification machines may be fitted with mechanical operation, adjusted on the baler itself). Very often, the amount of net expected to be applied to the bale is considerably less than actually wrapped on | the bale. The quantity of net applied should always be checked ON THE BALE, as the setting on the baler is only an ‘indication’ and should never be assumed to be accurate. There will always be variations in the amount of net on the bale, these are dependent on a number of important factors:- |

|

|

|

|

|

|

|

|

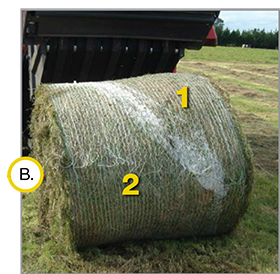

| Is crop still being fed into the baler as the net is being applied, so not all the net is on the outside? Correct net application should be fully to the OUTSIDE of the bale. It is important that once the net is being applied, forward motion of the baler should have stopped, so avoiding crop being taken is as the net is being applied. If this happens, the full ‘solding properties’ of the net will not be possible, as some of the net is now incorporated inside the bale, so reducing the ability of the net to secure the bale. |

|

Climate

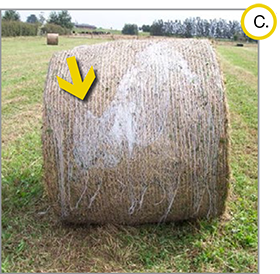

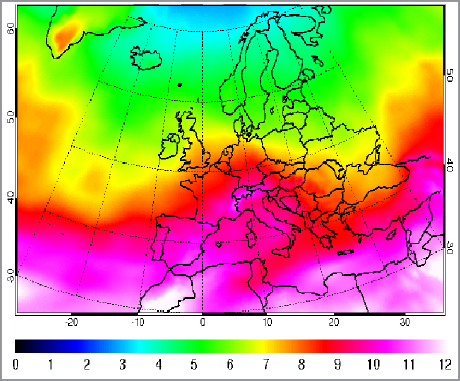

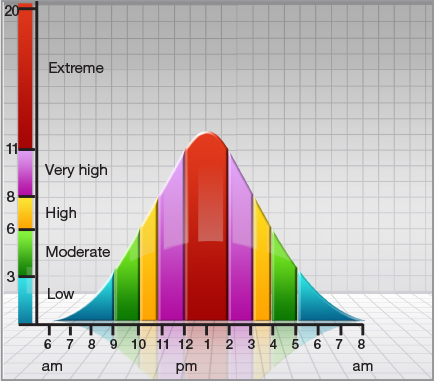

Certain regions of the world have higher U.V. radiation levels than others, caused by latitude, weather and climatic variations and air pollution levels. In these regions, bales stored outside with continual exposure to high U.V. radiation levels can suffer increased degradation of the netwrap.

|

|

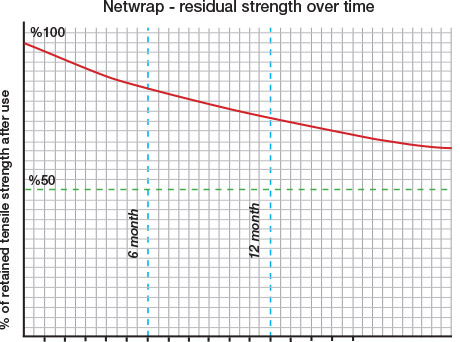

Netwrap tensile strength is at its greatest when first used. However, continued exposure to the elements, as well as being under ‘load’, when wrapped on the bale and holding the crop, all have an effect on the residual strength that the netwrap can retain. If used and applied correctly, netwrap is designed to maintain 50% of its applied strength over a 12 month period.

| It is important to consider these factors when making and storing bales in higher U.V. radiation regions. Where netwrap on a bale is under greater tension than recommended, due possibly to bale pressure or insufficient netwrap layers on the bale, the inherent strength of the netwrap can be reduced when exposed to higher U.V. radiation levels. Tama Netwrap is specially designed to hold the bale for at least 12 months and has UV stabilization to assure it will retain at least 50% of the original net strength after 12 months in the field. |

|

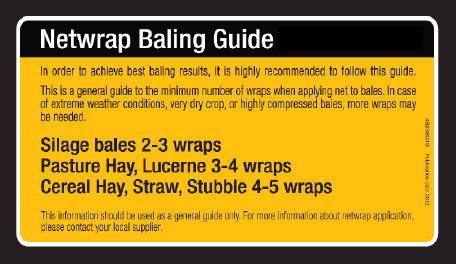

In order to achieve best wrapping results it is highly recommended to follow the instructions detailed below:

- Netwrap rolls (before baling) should be kept in their original packaging under cover, in dry conditions, to assure best performance.

- To reduce the risk of bursting bales and netwrap failure on the bale during storage, handling or use of round bales, it is extremely important that sufficient netwrap is applied during baling – in accordance with manufacturers’ recommendations.

- Ensure the netwrap (roll or netwrap on the bale) is not exposed to any type of agro chemicals, as this can affect the net strength and reduce the time the net will securely hold the bale.

Crop and Conditions

| The type of crop being baled and the way the bale will be handled afterwards have huge influences on how much net should be applied to the bale. There should ALWAYS be a MINIMUM of at least a 2 layers of net ON THE BALE, but the diameter of the bale, the actual type of crop and its characteristics when baled will determine the REAL MINIMUM amount of net to be used. |  |

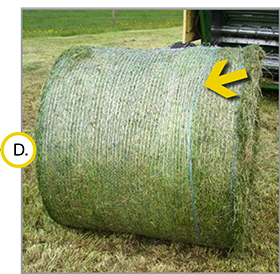

| Grass forage crops, such as silage, haylage, Alfalfa etc., are heavy leafy crops, often baled with a diameter of 1.2m – 1.5m and, when cut and baled, tend to be ‘inactive’ and do not have a characteristic for expansion. In general, the weight of the bale and the method of bale transportation are the main factors in deciding how much net to apply to the bale. It is important to remember that when baling silage, the amount of netwrap applied to the bale should not be reduced because of the film wrapping immediately or soon after baling. It has been proven that if fewer than minimum of 2 wraps of net are applied ON THE BALE, there is a high risk of the netwrap slipping and allowing the bale to expand. Bale expansion before or during wrapping brings two problems:- | Cereal crops, such as wheat, barley, etc. produce lighter bales and are, by comparison, more ‘explosive’ in their characteristic after baling. These longer, hollow-stem crops do not compress as well as a leaf crop and, consequently, are more likely to require a greater number of net layers for them to be safely contained. As these bales are, generally, not as heavy as leaf crop, the bale dimensions are typically greater, with bale diameter between 1.5m – 2.0m. Bales of this size mean a greater circumference and, therefore, a greater ‘energy’ contained within the bale. With a greater surface area of bale wanting to expand more, the netwrap is under considerably more pressure. In such cases, it is IMPORTANT that more net is applied to the bale to ensure adequate security of the bale. |

|

|

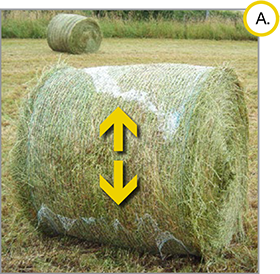

Bale Shape

| If the bale shape is not uniform, the net will be under varying tension from the un-even pressure within the bale. A bale which is not flat and uniform will have more pressure in the centre and so apply more pressure against the net in this place. This increased and excessive pressure against the net will create higher tension forces against the net threads causing one or more to break, which will, in turn, increase the tension on the remaining threads and, therefore, eventually cause more threads to break. Also, badly shaped bales, like this, will have more risk of damage on the ‘high point’ when being ejected from the baler or when being handled, because of the shape and higher net tension in this area. |  |